Mercury Marine’s new high-pressure die casting machine is now the largest in North America

Fond du Lac, Wis. - Mercury Marine held an event today to officially announce the commissioning of the largest high-pressure die casting machine in North America. Since 2009, Mercury Marine has now invested more than $800 million in R&D and manufacturing expansion at its Fond du Lac campus. This specific investment is a 4,500-ton BuhlerPrince machine. Installation began late in 2016 and was just completed in late March 2017.

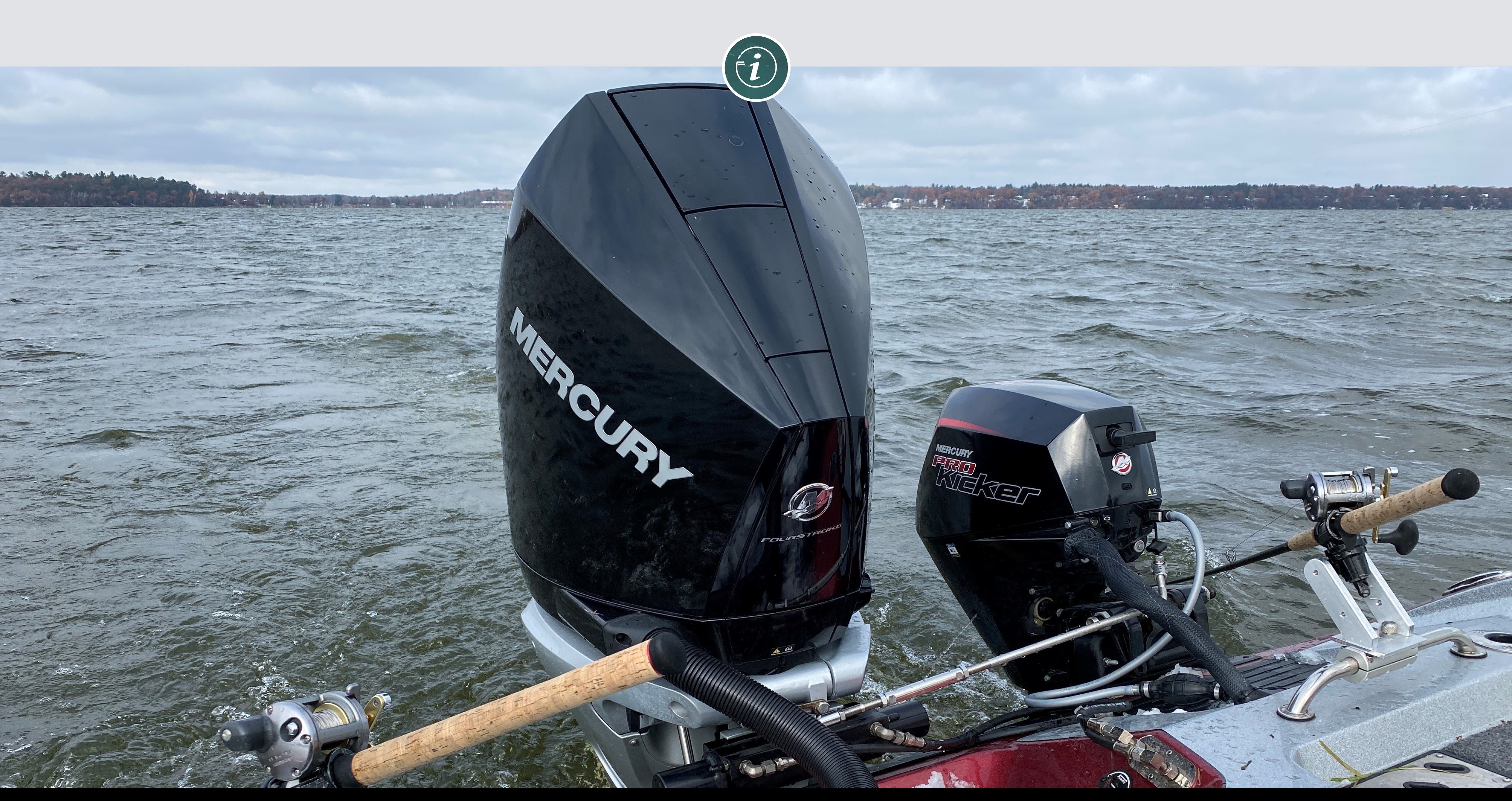

“This new machine positions us to make castings that no one else in the industry can do,” said Mike Meyer, general manager, Mercury Castings. “With this new machine, Mercury can make larger, lightweight structural components and reduce the overall weight of our engine by producing more efficient castings.”

The new machine has 4,500 tons of closing force with three industrial robots integrated into the cell. The total weight of the machine with tools and oil is more than one million pounds. The new machine can produce large, structural components for the high-horsepower marine segment, and even other segments such as automotive.

“This new, state-of-the-art casting machine on our campus gives us the opportunity to continue to drive growth for the business,” said John Pfeifer, Mercury Marine president. “This investment is one of many milestones on Mercury’s investment journey to support our customers now and into the future.”

Additional features of the new die cast machine:

- Integrated cell – automated to:

- Robotic metal pouring

- Robotic die lube spraying

- Robotic extraction from die cast machine

- Automated overflow detection to prevent damage to tooling

- Automated liner insertion into die cast machine

- Automated sawing of gates, eliminating ergonomic issues of lifting heavy castings/gating by operator

- Automated knockoff of venting and overflows, eliminating repetitive motion of hammering by operator

- Integrated part marking with 2D barcodes for part traceability throughout the product life

- Hood Filtration System

- Integrated hood system to capture process steam and vapors to be filtered before being re-introduced to the plant

- Produces the cleanest environment in the industry for our operators

- Tooling

- Highly engineered and complex die casting tools ran in the machine

- Utilization of pressurized hot water equipment (up to 300 degree F) and high pressure jet cooling lines (flow rates up to 500 PSI)

- Over 100 water lines to help keep the tool in thermal equilibrium during the process

- Parts Produced in Cell

- Extremely complex and large aluminum die castings

- Ability to pour casting shots up to 200 lbs.

- Extremely complex and large aluminum die castings